Table of Contents

Shrinkwrapping

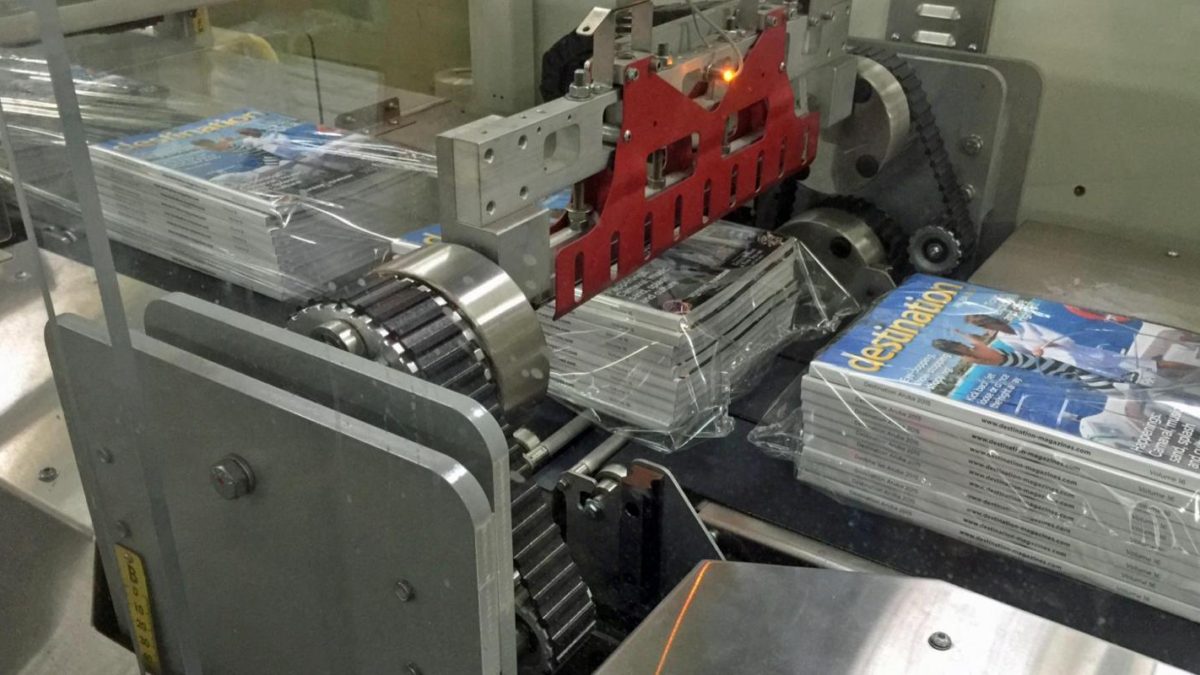

Shrinkwrapping is a particular type of packaging method in which an individual polymer plastic sheet is rolled over any material of your own choice. The shrink wrapping method is best to save the products from any damage. The wrapping gets so tight that no air can enter through it so you can easily pack your products in this wrapping without waiting for any second thought.

The shrink wrapping is also known as the overwrapping method, and the polymer plastic sheet used is polyolefin film. The film is quite clear, and it offers excellent clarity when you want your product to be prominent even after being packed. The shrink wrapping is used to get multi-packs or on packs most of the time. The polyolefin film is quite expensive, but on the other hand it gives god performance as well.

The process of shrink wrapping

Shrink wraps should be possible with the assistance of moved polyolefin material and can be utilized as much as required. It very well may be fixed utilizing heat. This is fundamentally appropriate to little machines. Then again, pre-framed polymer plastic sacks are accessible in various shapes and sizes. The item is put inside it and after that shrink-wrapped. The pack is then put through a warmth procedure, because of which the sack takes that state of the item. It is an excellent method to verify an item and shield it from the encompassing climate.

The method of shrink wrapping

Determining equipment

It is essential to decide on the stuff that is going to be used in the shrink wrapping method. There is a total of three steps that you need to overcome before starting with your shrink wrap method. The first one is to know about the type of shrink film that is going to be used. The second is to get the heat sealer that will help you to close the open ends of the wrap or film. And last but not least to get the heating source that will provide heat to the shrink wrap and it will shrink and tightens the product packaging.

Proper measurements

The next step to get your product shrink-wrapped is to measure your product. The measuring of the product will make sure that which forms of shrink file you need to consider and what size it should be. Other than that, you will have a clear idea about the size of the heat sealer and the shrink tunnel if required. The measurement of large products must be done as length*width*height.

Seal the open ends

Once you are done with the measurement of the product, now it’s time to put the product inside the shrink film. Use a heat sealer to close the open ends of the film around the product. Make sure that you leave an inch from the product while sealing the ends.

Apply heat

The last step to shrink wrap your product is to apply some heat to it with the help of shrink gum or tunnel. The gun will shrink the wrap and will give a tighten texture to the product.