Table of Contents

Pad printing

Pad printing is a unique printing method that lets the user transfer a 2D image onto a 3D item. This type of printing is used to get the prints on the items that are hard to be printed like concaved surfaces or huge items. This printing method got its popularity during the world war, kit happened when the watchmakers started to make designs on the concave surface of the watches. Pad printing is a method that makes it possible to print on uneven surfaces and even on those surfaces on which no other printing method works. This is major reason for which most the industries such as cosmetics, medicals and electronic industries use this printing method.

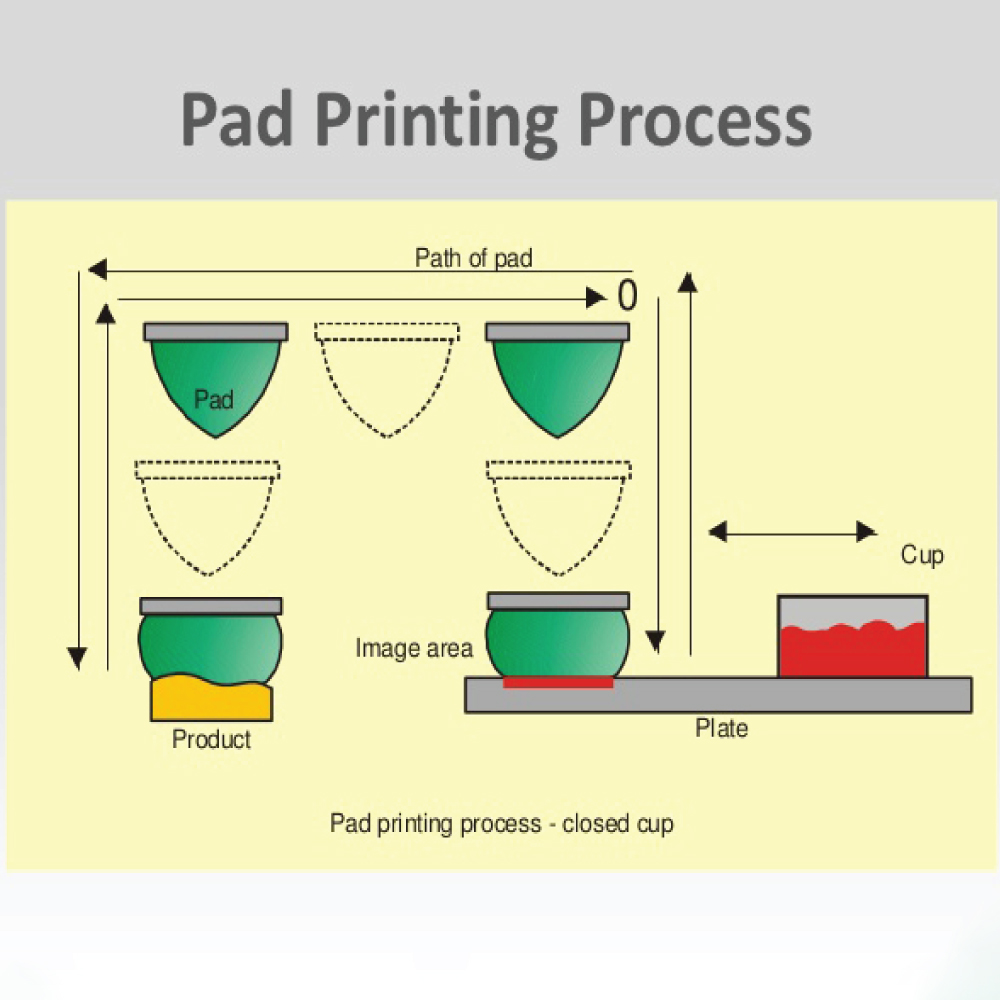

How does pad printing works?

Pad printing utilizes the silicon pad that helps to print the design on the item you want to print it on. The printing machine keeps the item tight by holding it, and it is passed through the inked plate. After it has been passed through the inked plate then it is stamped by the pad. Pad printing can easily enhance the beauty of the 3D parts; this is because when the image is printed on such parts, the pad changes into the shape of that part. During this shape adaption, the design of the image is not affected. Pad printing is recommended to be used because it gives excellent fine details and remarkable finishing to the item. You can design the print with multiple colors by using the pad printing method.

Benefits of pad printing

One of the fundamental focal points of pad printing is that it can print on probably the most unprintable items possible. The silicone cushion adjusts to the state of the part so it can undoubtedly print on uneven surfaces, raised, and sunken and barrel-shaped. This technique is additionally useful for fragile items that would almost certainly break utilizing different strategies for printing, for example, screen printing. It additionally gives unpredictable itemizing on littler surfaces, for example, standardized identifications, logos, and marks. Contingent upon the ink type, this printing technique can likewise be utilized on items that need high opposition against scraped spots or synthetic substances. Pad printing is additionally incredible for multicolor printing without the requirement for quick drying. Check Pad printing definition here.

Inks used for pad printing

Pad printing inks are made specially to match perfectly with the type of material on which the designs are to be printed. You can get variations of ink lines for almost all type of plastic materials such as ABD, nylon, HIP, and many other materials. You would be amazed ton read that the hardest material such as polythene, Delrin, Urea, etc. are also capable of being printed with the pad printing method. Most of the inks that are used in pad printing are solvent-based while other is UV based. The solvent-based ink is cured as the time passes, or some heat is added into them to enhance their consistency and lifetime. And the UV based inks are cured with the help of UV light. Order the printing of boxes and packaging here.