Table of Contents

Flexographic printing

Flexography is an advanced version of letterpress printing. This is such an amazing printing technique because it was compatible with almost any kind of material. No matter you want to print paper, cardboard, corrugated cardboard, fabrics, cellphones, utensils and you name it, this printing method is best for it.

The use of semiliquid ink gives this printing method another thumbs up because the drying process of the ink and the print is quite affected when this quick-drying ink is used to make amazing prints. In this era of digital printing, flexographic printing knows it better how to make it place in the printing industry constantly. This printing method is most commonly used for the printing of packaging for the products and the labeling of those packaging (offered at City Of Packaging).

How does it work?

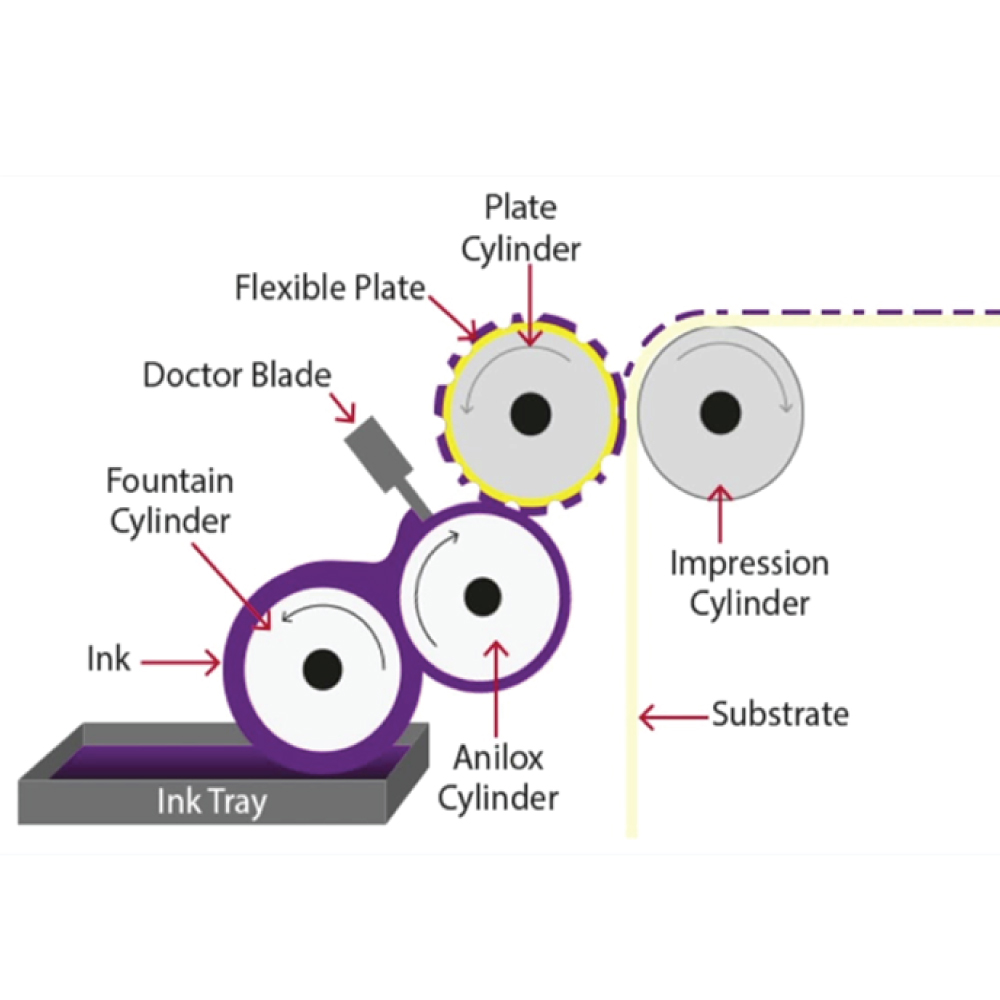

The working of flexographic printing is quite simple; it uses flexible photopolymer printing plates that are folded all over the rotating cylinders present on the web press. The plates are already inked, and they have a bit of raised design on them, and they revolve at high speed due to which the design is transferred on the material you want to print it on. Flexographic inks are good enough because they can make the wonderful print on almost all types of absorbent and nonabsorbent items.

Flexographic printing goes very well with the print that is of continuous pattern like the gift wraps. The gift wraps have a continuous pattern that is obtained by flexographic printing. This printing method is different from offset printing as in offset printing individual sheets of paper are used to get the print. But, with flexographic printing huge rolls of material are used that make it easier for the user to get prints without any interruption. For More details and process read this article.

Why use flexographic printing?

All the printing methods have their advantages. Similar to all the other printing methods, flex printing has the benefits that make it unique from all other types of printings. Flexographic printing is no doubt considered as the best printing method for long print runs. Below mentioned are a few advantages of flexographic printing:

Quick production speed

Flexo press is popular for their speed; they can give a speed of about 300 meters per minute. And to be honest that a really good speed for nay printing presses. The setup time required for flexographic printing is quite less if compared with other printing types. This printing method is the perfect match for those who are finding something that is extraordinary.

Low maintenance and cost-effective

Flexographic printing is considered too much cost-effective than other printing techniques. The machines and the equipment used in flexographic printing do not require much maintenance that means that you can save a lot from that. All the other printing machinery does require regular maintenance if you need them to work properly and have a long lifetime. But, with flexographic printing, it is assured that you won’t have to spend money on the maintenance and the machinery and equipment will work for a long time.