Table of Contents

3D printing

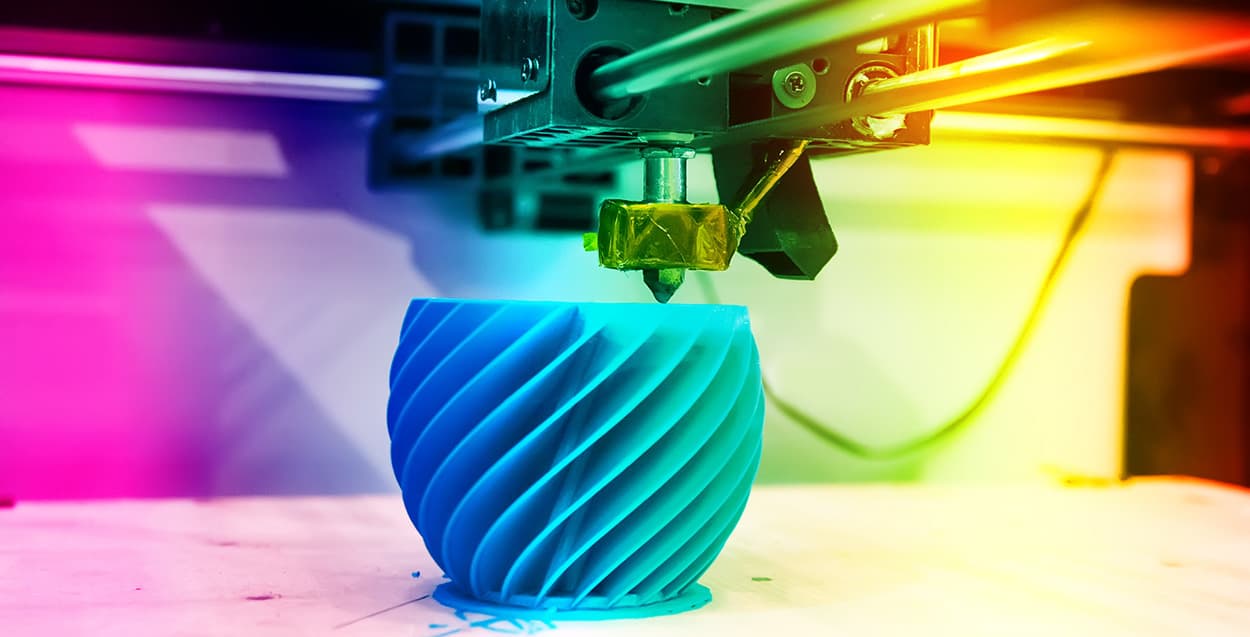

Technology has been spread all over the world, then why not in the printing industry? Leave the old printing methods and adopt the new 3D printing methods to give magical texture to your printing objects. 3D printing is also named additive manufacturing; it is the procedure of designing three-dimensional hard materials with the help of computerized files.

To get the right 3D hard objects through 3D printing, special additive processes are used. The additive process is the process in with the object is designed and manufactured by giving multiple layers of the material until the desired design is achieved. All these layers of the material are just like thin slices that are kept horizontally to get the desired design. 3D printing allows the user to make difficult designs as well easily without much effort and cost. It is an affordable method of making solid objects than those old printing or manufacturing methods.

Process of 3D printing

The 3D solid objects undergo three basic steps of 3D printing. All the three steps of 3D printing in the 3D processing are mentioned below:

First step

This is the initial step of 3D printing where you prepare the design you want to get printed. Here the 3D file design is made that you want to turn into solid object and this step is the most important one of the entire procedure. To make the 3D file you can use multiple ways, such as CAD software, 3D scanner or you can also download a premade 3D design from any online site. Once you are done with the designing of your 3D file, now you are ready to move forward towards the second step.

Second step

The next step leads to the genuine printing process. To start with, you have to pick which material will best accomplish the particular properties required for your article. The assortment of materials utilized in 3D printing is exceptionally expansive. It incorporates plastics, earthenware production, pitches, metals, sand, materials, biomaterials, glass, and even lunar residue! The greater part of these materials likewise take into account a lot of completing choices that empower you to accomplish the exact plan result you had at the top of the priority list, and some others, similar to glass, for instance, are as yet being created as 3D printing material and are not effectively open yet.

Final step

This is the finishing step of 3D printing, and it should be done by some experts and professionals because here either you can ace your object or you can destroy it. This step needs a lot of expert skills and materials as well. At the final stage of 3D printing the object you need to get is painted, lacquered to attain the exact finish that you imagined. The finishing material should be chosen perfect ones because the final results of the 3D printing will be visible after this final stage. To get the best results get good knowledge about 3D printing before starting to make your 3D prints.

Other Printing services

check our printing services

-

Custom Cardboard Door Hangers

Custom Cardboard Door Hangers -

Custom Menus Printing

Custom Menus Printing -

Custom Carbonless Forms

Custom Carbonless Forms -

Custom Envelope Printing

Custom Envelope Printing -

Custom Flyers Printing

Custom Flyers Printing -

Custom Magazines Printing

Custom Magazines Printing -

Custom Greeting Cards

Custom Greeting Cards -

Custom Calendar Printing

Custom Calendar Printing -

Custom Vinyl Banners

Custom Vinyl Banners -

Custom Tags Printing

Custom Tags Printing -

Custom Table Tents

Custom Table Tents -

Custom Folders Printing

Custom Folders Printing -

Custom Decals Printing

Custom Decals Printing -

Custom Cd Jackets

Custom Cd Jackets -

Custom Business Cards Printing

Custom Business Cards Printing -

Custom Brochures Printing

Custom Brochures Printing -

Custom Bookmarks Printing

Custom Bookmarks Printing -

Custom Booklets Printing

Custom Booklets Printing -

Custom Bags Printing

Custom Bags Printing