Table of Contents

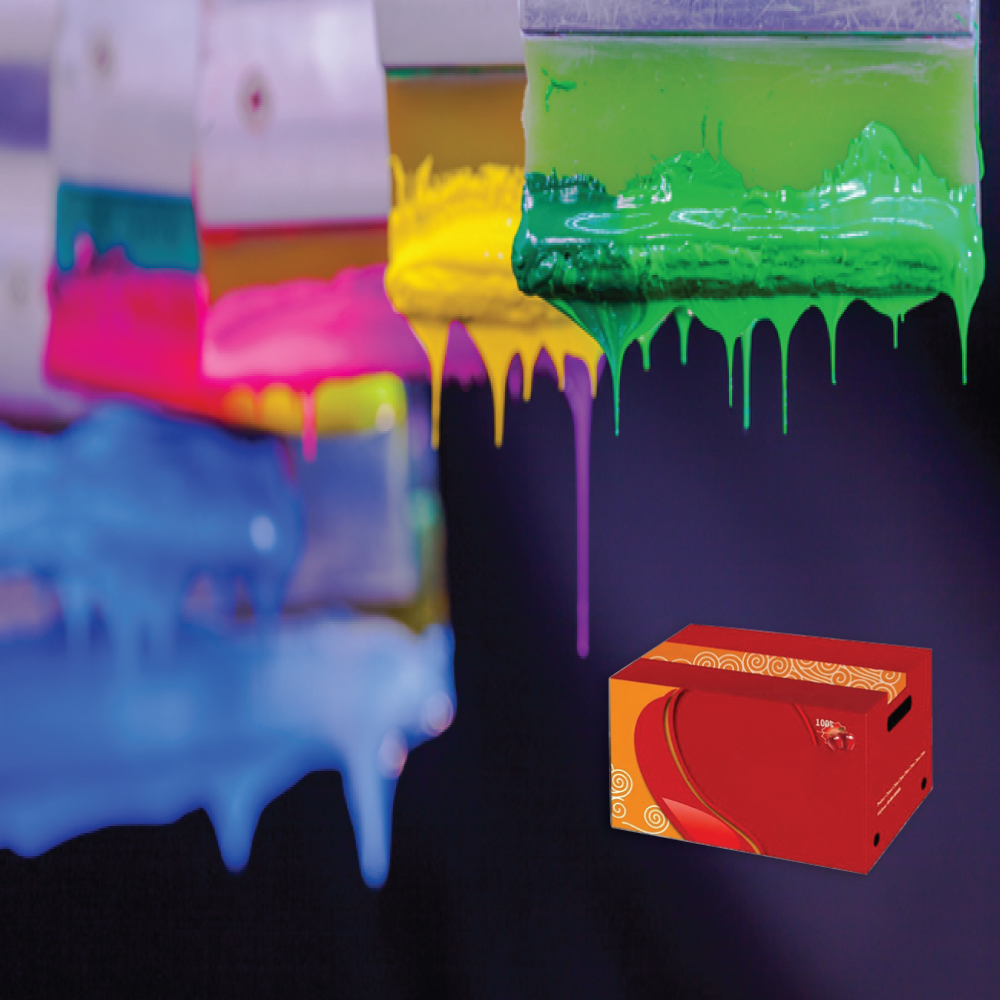

Printing press

The printing press is a great invention of a German named Gutenberg in 1439. The printing press is a machine that helps to print the text or the images on paper or any other material with the help of special ink. This is one of the best inventions to date because, before this invention, most people remain illiterate because there was no means of printing books so that the people could read them and gain knowledge. Old methods of printings were used to print any letters on paper, but that was quite time-consuming. Because of the printing press, human life has become much more comfortable and it has affected the entire world.

How does the printing press work

There are two types of printing presses used most commonly in the printing industry. Below mentioned is the working procedure of both the printing presses.

Flatbed printing press procedure

The flatbed press is the simplest version of letterpress machine that was invented by Gutenberg. The flatbed press is also known as platen press because the paper that is to be printed is let on the sleek metallic plate that is named as platen. The platen is kept under the second sleek plate on which the relief design of the product that has to be printed is kept. This second plate is called the printing plate. The printing plate is filled with the ink, and the ink is spread all over the printing plate with the help of an automatic roller. This is done before the paper is kept on plate and pressed with much power to get the print on it. Once the paper is pressed, it must be released soon because the design on the printing plate will be transferred on the paper immediately.

Flatbed presses are commonly the slowest of all printing strategies since it sets aside some effort to continue lifting and inking the printing plate and stacking and evacuating sheets of paper. That is the reason most letterpresses use turning chambers instead of either of the level beds.

Offset printing press procedure

Present-day balance lithography printing presses utilize a refreshed variant of a similar essential thought wherein the stone is supplanted with a slim metal printing plate.

To begin with, the picture to be printed is moved photographically to the plate. The pieces of the plate from which the picture is printed are covered with polish (clear varnish), so they draw in ink, while the remainder of the plate is covered with gum, so it pulls in water.

The metal plates are bent around a printing chamber and press against a progression of rollers, which hose them with water and after that brush them with ink. Just the lacquered pieces of the plate those that will print, get ink. The inked plate presses against a delicate elastic (balance) chamber, known as the blanket chamber, and moves its picture over. The chamber at that point presses against the paper and makes the last print.

Other Printing services offered by City Of Packaging

-

Custom Cardboard Door Hangers

Custom Cardboard Door Hangers -

Custom Menus Printing

Custom Menus Printing -

Custom Carbonless Forms

Custom Carbonless Forms -

Custom Envelope Printing

Custom Envelope Printing -

Custom Flyers Printing

Custom Flyers Printing -

Custom Magazines Printing

Custom Magazines Printing -

Custom Greeting Cards

Custom Greeting Cards -

Custom Calendar Printing

Custom Calendar Printing -

Custom Vinyl Banners

Custom Vinyl Banners -

Custom Tags Printing

Custom Tags Printing -

Custom Table Tents

Custom Table Tents -

Custom Folders Printing

Custom Folders Printing -

Custom Decals Printing

Custom Decals Printing -

Custom Cd Jackets

Custom Cd Jackets -

Custom Business Cards Printing

Custom Business Cards Printing -

Custom Brochures Printing

Custom Brochures Printing -

Custom Bookmarks Printing

Custom Bookmarks Printing -

Custom Booklets Printing

Custom Booklets Printing -

Custom Bags Printing

Custom Bags Printing